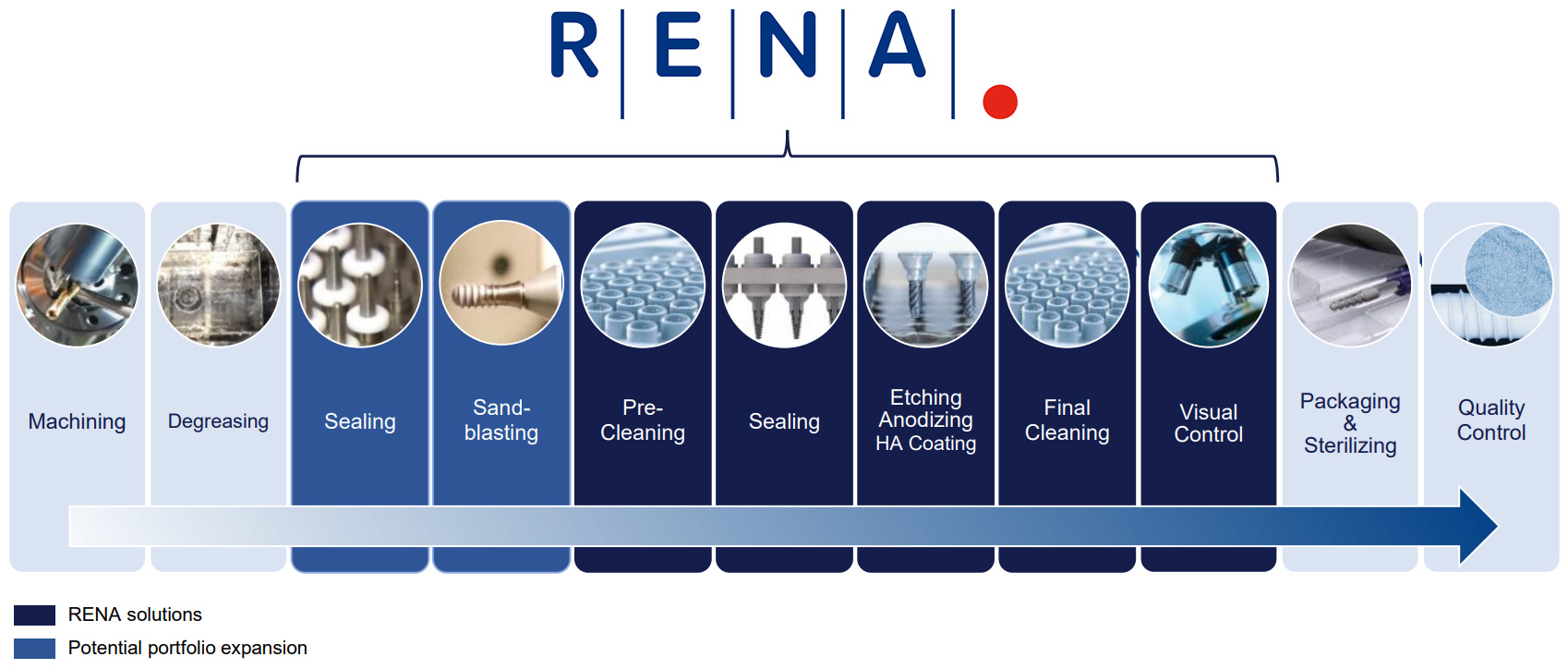

RENA has a vast experience in developing tools and process for the wet-chemical treatment of surfaces of medical devices.

In offering Service Finishing for Dental Implants we are following a long standing request of our customers. Any producer of dental implants will now be able to enjoy the benefits of our top notch experience in wet-chemical surface processing of medical devices without having to worry about high upfront investments in machinery.

Wet-chemical etching

We guarantee a high surface quality

Depending on your preferences we can use chemicals according to your established recipes. Or we draw from our processes and recipes to achieve whatever surface parameters you are looking for. Our experience with a large array of chemicals and process parameters allows us to achieve almost any conceivable surface quality.

Sandblasting

We offer sandblasting and etching for a perfect surface

We work closely with a sandblasting partner and can – where required – coordinate that step of surface treatment for you, too. Especially when it comes to new products we’d also encourage you to test omitting sandblasting – we are pretty confident we can achieve similar surface structures with just our etching processes.